Shreedevi Sahadeo made her way to the podium; perhaps a bit nervous but handling it well. She was presenting her final engineering project, one of four standouts for the academic year along with Yvan Dass, Salisha Khan and Harold Raghubir. And in the audience before them were staff and students from the Department of Mechanical and Manufacturing Engineering, St. Augustine administrators as high up the chain as Campus Principal Professor Brian Copeland and guests from sectors as varied as manufacturing, tourism and agriculture. Shreedevi Sahadeo made her way to the podium; perhaps a bit nervous but handling it well. She was presenting her final engineering project, one of four standouts for the academic year along with Yvan Dass, Salisha Khan and Harold Raghubir. And in the audience before them were staff and students from the Department of Mechanical and Manufacturing Engineering, St. Augustine administrators as high up the chain as Campus Principal Professor Brian Copeland and guests from sectors as varied as manufacturing, tourism and agriculture.

In her project she outlined how she had researched the deficiencies in local greenhouse agriculture, designed and made a model of a much more efficient greenhouse. It was the kind of research that in the right hands, with the right funding could contribute to the revitalisation of food production, in a time when food security is a great concern.

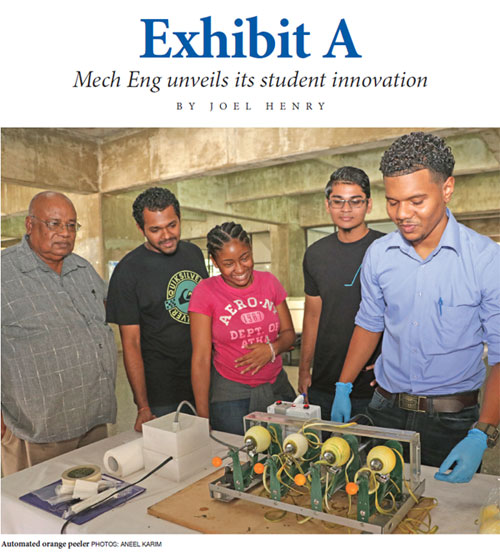

In fact, all the projects – from an automated orange peeler that smoothly removed the skins of four fruits at once, to research on measuring the integrity of roofs for solar panels, to a company specific plan for optimising warehouses for one of Trinidad’s major food processing companies – could potentially form the basis for viable products or processes that could create value for Caribbean economies.

But most impressive of all, just outside in the Undercroft of the Kenneth S. Julien Building of the Engineering Faculty was an entire exhibition of projects, the work of over 120 students. Innovation on display.

“What you are seeing here is a seed that we will make grow”

Titled “The Final Year Exhibition of Engineering Students: Design and Build,” the two-day event was created by key personnel within the Mechanical and Manufacturing Department for several reasons. Firstly, it encourages students with an interest or inclination for innovation by recognising their work. As it stands there are several cultural and structural disincentives for anyone with such passions.

Secondly, it brings sectors that could benefit from research and development together with new ideas and idea generators. Among the organisations in attendance were the Trinidad and Tobago Manufacturer’s Association, the Tourism Development Company, the National Agricultural Marketing and Development Corporation and the Agricultural Development Bank.

The exhibition also makes a statement about UWI and its role as an agent of regional development through research and development that is responsive to the needs of the Caribbean.

“[Universities] are supposed to be the ones who are on the cutting edge,” said Professor Copeland. “That’s what allows for the growth and development of science and technology. Then we further harness that science and technology to create products and processes.”

The May 2016 exhibition is the second since the idea became reality in 2015 but this year the energy seemed more urgent, perhaps because of the starkness of the region’s economic fortunes.

“As with any business sector we know that opportunity is critical and timing is everything, and with the recession there is opportunity,” said Franka McKenzie, Director of the TTMA. “It is no coincidence that there are so many ‘Made in T&T’ and ‘Buy Local’ campaigns. It is because there are more opportunities. We see it right here. We see it with the products on display.” “As with any business sector we know that opportunity is critical and timing is everything, and with the recession there is opportunity,” said Franka McKenzie, Director of the TTMA. “It is no coincidence that there are so many ‘Made in T&T’ and ‘Buy Local’ campaigns. It is because there are more opportunities. We see it right here. We see it with the products on display.”

Professor Copeland made similar statements, telling the audience that fostering innovation was one of his mandates as Campus Principal.

“We live in an opportune time,” he said.

Projects at the exhibition fell into five categories: dynamics, automotive, agriculture and agro-processing, manufacturing and alternative energy, and environmental and medical. Because food processing in particular is seen as an especially necessary and viable area for growth, several related projects were highlighted. These included, among others, an automated duck roaster, a pulveriser for oyster shells, a cassava harvester, and even one that demonstrated the thermal insulating properties of banana plant leaves.

Both the exhibition organisers and guest speakers acknowledged that the culture of innovation being fostered by the exhibition is still in its earliest stages. Mr. Rodney Harnarine, Development Engineer with the Mechanical and Manufacturing Department and one of the Campus’s most dedicated advocates for practical research and development, told those in attendance, “What you are seeing here is a seed that we will make grow.”

Listening to students such as Yvan, Shreedevi, Salisha and Harold – inventive young people with their whole professional lives ahead – the enormous potential is evident. The aspiration in this new era is that institutions such as The UWI, the private sector and regional governments nurture that potential.

AGRI-BASED PROJECTS (2016)

- Melangeur for Chocolate Production

- Cocoa Bean Winnower

- Robotic Arm for Industrial Spraying

- Pulveriser for Oyster Shells

- Thermal Insulating properties of Banana Leaves

- Automatic Duck Roaster

- Coconut Picker

- Collector for dried leaves

- Manure cake remover

- Hand held Fertilizer Applicator

- Cassava Harvester

- Automated orange peeler

- Automated cassava peeler

- Coconut water extractor

- Bamboo Bed

AGRI-BASED PROJECTS (2015)

- Chataigne Shredder

- French Fry cutter for cassava, sweet potato, plantain

- Black Eye sheller

- Tomato Grader for size

- Pigeon Pea Sheller

- Cocoa Pod Splitter

- Channa Splitter

|