From a vertical wind turbine to a miniature controlled atmosphere greenhouse, there was lots of applied technology on display at the recent annual exhibition held by the Department of Mechanical and Manufacturing Engineering. From a vertical wind turbine to a miniature controlled atmosphere greenhouse, there was lots of applied technology on display at the recent annual exhibition held by the Department of Mechanical and Manufacturing Engineering.

The exhibition, held on Wednesday May 23 at the JFK Auditorium, showcased undergraduate final year projects in a wide range of categories, and was the companion outreach event to the Faculty’s conference event held earlier that morning.

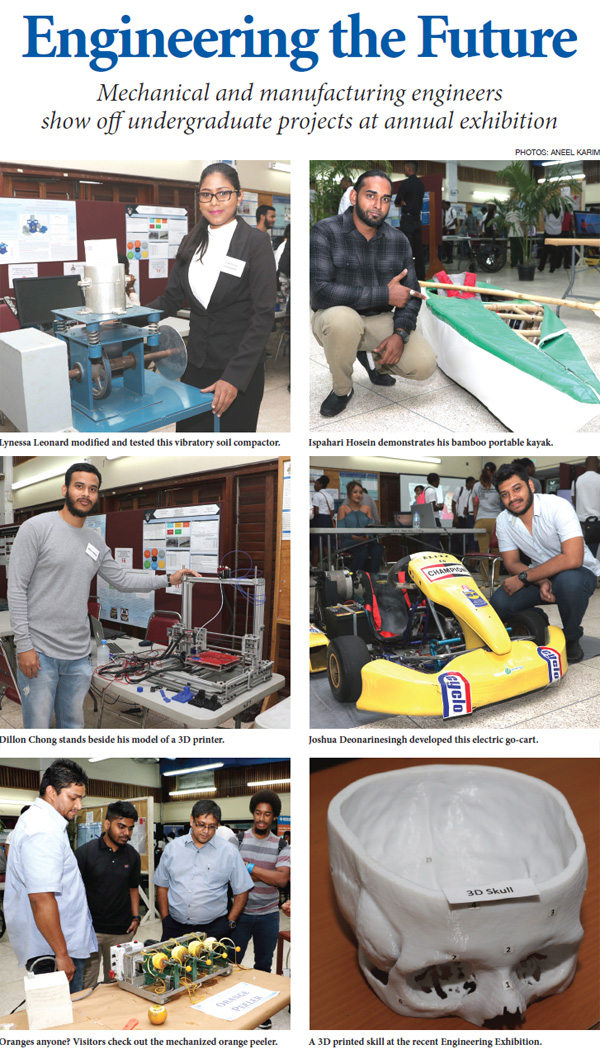

Among the exhibits was an electric Cadet-class racing go-cart for the Caribbean region by Joshua Deonarinesingh, who is completing a BSC degree in Mechanical Engineering – Applied Mechanics. His go-cart was an eye-catching cheerful bright yellow, and uses increased electrical drive systems for a greener, more eco-friendly go-cart.

“The Cadet class is an introductory class of go-cart racing types used for leisure or competitive purposes,” explained Deonarinesingh. “Currently there are no electric models in T&T, but there are equivalent Cadet class gas go-carts. I wanted to eliminate fossil fuel burning and gas emissions while achieving comparable performance with the gas go-carts. I completed the project, but there are several initiatives that could be implemented for a better project.”

Another interesting display was a range of hard plastic objects all generated by 3D printers, an innovative solution to parts requiring custom-made design or parts no longer being manufactured and readily available. These display objects included a model toy car, a component for an older model of motorcycle, and a very lifelike human skull. The technical term for this manufacturing process is Additive Manufacturing: it allows users to make three-dimensional objects from computer-generated 3D models.

The UWI acquired a high-end Fused Deposition Modelling (FDM) machine some years ago. The 3D printer, a Fortus 400mc manufactured by Stratasys, cost approximately TT$1.25 million and is a rapid prototyping (RP) technology, meaning that it can create 3D objects primarily for prototyping purposes. Several students in the Manufacturing Engineering department showed projects related to 3D printing, including Dillon Chong who was testing a model of a 3D printer. Meanwhile Arshad Mohammed, a PhD student in Manufacturing, wants to research aspects of traditional machining and 3D printing, saying: “There are advantages and drawbacks to both; I want to look at ways to combine them, to build on the strengths of both of them.”

Some projects at the exhibition used easily available local raw materials to create unique, fun local products, such as the portable bamboo-framed kayak designed by student Ispahari Hosein. The exterior casing could be zipped over the bamboo frame and it looked extremely light and portable.

Undergraduate student Lynessa Leonard decided to modify and test an existing vibratory soil compactor designed by Anika Taylor in 2015, to test the maximum density of soils. There were several projects like this which took useful ideas from past years and improved on them or meticulously tested an aspect of them, demonstrating the necessary ongoing experimental research involved in developing or improving manufactured products.

Other interesting projects included: Modeling of vibration transmission in offshore platforms using statistical energy analysis; a solar-powered water purification system; waste heat recovery in combustion engines; a cocoa-picking rod; a miniature controlled atmosphere greenhouse; and a cryogenic freezer for food products. (SAA) |