Because Trinidad and Tobago’s economy has been and continues to be heavily dependent on the petroleum industry, there is an urgent call for diversification.

In terms of global trade for petroleum products, new sources have led to over-production in the last three years and this has forced the price of oil and gas downwards. From a high of over $100 per barrel it went down to around $40 a barrel. It is now rising and fluctuating around $50 per barrel.

These changes can be destabilizing at many levels and we have to look at developing non-oil sectors urgently, particularly in the areas of manufacturing, tourism and agriculture.

The UWI can be a major catalyst in diversification through our teaching and outreach programmes.

MANUFACTURING

In the early 1960s, there was an attempt to stimulate manufacturing by setting up industrial estates and encouraging the establishment of “screwdriver” industries (assembly-type).

Fifty years hence, many of those industries have either collapsed or are not sustainable because they could not respond to external factors, the major one being the inability to compete in a global free trade scenario.

In consultation with our stakeholders in manufacturing, we have set up MSc Degree programmes in Production and Manufacturing Engineering, with the primary focus of making companies more competitive.

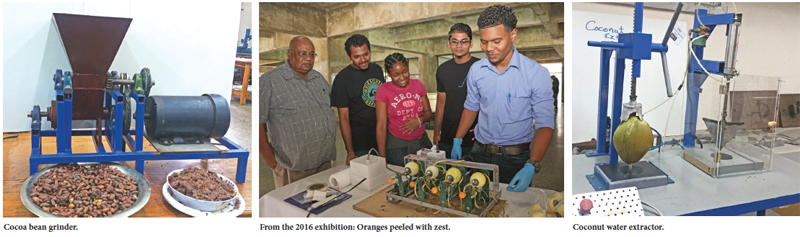

For the Open Day exhibition, students have worked on designing and building equipment in the following areas: Motion and Dynamics, Agriculture and Agro-Processing, Automotive Engineering, Environmental Engineering, Controls and Automation, Thermodynamics and Heat Transfer, Solar and Other Renewable Energy Sources, Medical Engineering and Manufacturing with Emphasis on CNC and Robotic Engineering. In their final year, the students will undertake to solve an engineering problem by designing and building a piece of equipment in one of these areas.

As part of the exhibition, demonstrations of 3D Printing and CNC Machining will be set up in the CNC lab.

AGRICULTURE

Trinidad always had an agricultural economy based on plantations producing cocoa and coffee, sugar, coconuts and rice, but since the 1960s there has been a steady decline and many farmers found it difficult to survive in a competitive commodity market. More so, there has been a steady decline in the availability of labour for agricultural production.

The Faculty of Engineering has been designing and building equipment that adds value to agricultural produce while simultaneously facilitating storage, especially when produce is seasonal.

In the last 10 years we have designed and built equipment to process coconuts, both green and dry; cassava; plantain; sweet potato; cocoa; dasheen; pigeon peas, and other crops.

Cocoa is a special case; we produce high-grade cocoa and export it to developed countries where buyers convert it to high-grade chocolate attracting premium prices on international markets. The Faculty is trying to bridge this gap in the production of high-grade chocolate.

The Faculty of Agriculture has teamed up with the Faculty of Engineering and we have been able to build several pieces of equipment for the cocoa production industry.

We were able to build a successful cocoa pod splitter and to the best of my knowledge this is a first in the world. Most of the equipment has commercial potential.

COCOA POD SPLITTER: We have developed a machine to split the cocoa pod so that the beans can be removed without any injury to the seeds. When fully operational, this machine will separate the seeds from the pod with a minimum of effort. The machine is portable and can be transported to the field.

CASSAVA PEELER: Composite flour consists of starches up to 20% that is non-wheat. This is healthier and more nutritious than pure wheat flour. Cassava, breadfruit, and sweet potato are grown locally and are good candidates for composite flour. We have built a cassava peeler that will remove the skin mechanically.

BREADFRUIT PEELER: Breadfruit is a starch rich in nutrition and fibre. To facilitate the processing we have built a breadfruit peeler that will mechanically remove the outer skin.

FISH SCALER: Because of the high price of fish, particularly during the Easter period, the production of fresh water fish has been on the increase and in order to process the fish for the retail trade, a fish de-scaler was built. This device will de-scale a fish in seconds.

COCONUT WATER EXTRACTOR: A coconut water extractor was built for persons selling coconut water to the public. It has the capability to drain the coconut water into a sterilized container and then cut the shell into three parts for those who may want to eat the coconut jelly. With proper sterilization of package and tools, a shelf life of 10 days can be realized without refrigeration or cold chain.

AUTOMATIC COCONUT GRATER: This is a useful piece of equipment to have in the kitchen to grate dried coconut meat to be used in cooking or for the production of coconut oil.

The Faculty of Engineering will be holding its fourth annual conference and exhibition on May 25 at the St. Augustine Campus. The exhibition will be open from 8am to 5pm at the JFK Auditorium and the conference will be on from 9-11.30am at Lecture Theatre 1, Chemical Engineering Block.

For more information, please contact the Mechanical and Manufacturing Engineering Department or Rodney Harnarine at rharnarine@gmail.com

Mr. Harnarine is a development engineer at the Department of Mechanical and Manufacturing Engineering, at The UWI, St. Augustine.

|