SUNDAY 3RD AUGUST, 2014 – UWI TODAY

11

ENERGY

RESEARCH

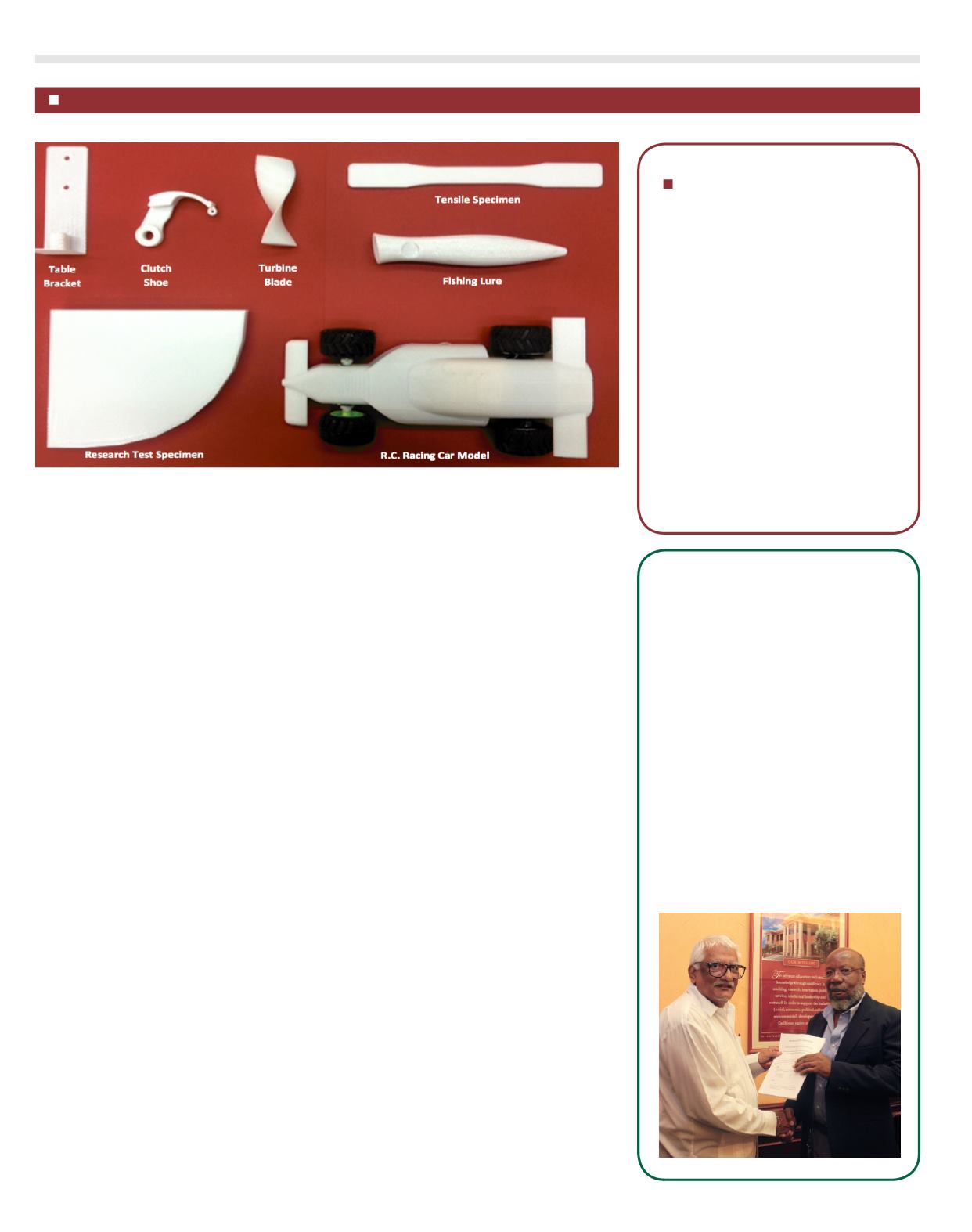

components are imported. Without violating intellectual

property rights, 3D scanning and printing technology

allows us to very easily model and manufacture prototypes

for most items. And from these prototypes they can be

mass produced.

3D printing and competitiveness

Whenspeaking tomembersof theFacultyofEngineering

concerned with innovation and competitiveness, the

importance of “time” is a consistent theme.

“Time is the key,” says Professor Brian Copeland, Dean

of the Faculty of Engineering. “You have to get there fast.

You do your utmost to get it done to the highest possible

standard within the window of opportunity.”

This is one of the main reasons that 3D printing is so

compelling to Dr. Chowdary and the MME Department.

3D printers are an “on-demand” technology. For example, a

patient with a bone fracture could potentially have the bone

scanned, have the scan converted into a 3D image, have that

image printed, and provide himwith the necessary prosthetic

before he leaves the doctor’s office. This is impossible with

conventional manufacturing since a prosthetic designed

specifically for a patient’s shape, weight and structure would

require iterations of models and trials.

Dr. Chowdary says, “When we need to compete

internationally, time counts. If we are behind, someone else

will take our position.”

Havingcommittedhimself to the causeofmanufacturing

engineering in the region, Dr. Chowdary is an almost exact

blend of urgency and patience. In his almost 12 years with

the faculty he has seen the progress of manufacturing

engineering achieve successes and suffer setbacks. With the

support of the Faculty of Engineering, the broader university

and even the Government of Trinidad and Tobago, he has

overseen the restructuring of the CNC Laboratory; the

acquisition of equipment like various CNC machines such

as mills, lathes and routers; a 3D scanner and now the 3D

FORTUS printer.

InSeptember 2014 the facultywill launch its restructured

MSc in Manufacturing Engineering and Management, a

research degree programme for both full and part-time

students that stresses linkages between the university and

industry. The programme, Dr. Chowdary explains, was

developed in part to meet the needs of the manufacturing

sector:

“We are in touch with the industry since 2004 and

continuously survey the local manufacturing industry

operations to find out how we could more effectively

support them. What we found, especially among small-

scale participants, was that they wanted to implement more

advanced and effective technology solutions but could not

afford to send their personnel abroad for training.Thus there

is a need for trainedmanufacturing engineers andmanagers

and UWI should work to meet that need.”

It’s been challenging. The discipline of engineering is

very much tied to oil and gas, by far Trinidad and Tobago’s

most dynamic sector.This has lead to inertia in building new

courses of study in areas likemanufacturing engineering and

management which are important for diversification.

“Initially, some people were not enthusiastic,” Dr.

Chowdary says. “From their perspective they are right.

The country has had a successful oil and gas sector for

20 to 30 years. These are the jobs students are looking for

when they graduate. ‘Why struggle with manufacturing?’

they ask me.”

He says, “I tell them that approach is not right. Oil

and gas are finite resources. What happens when they are

exhausted? Don’t expect overnight that God will come

and save the economy. We have to come up with ways

and means to generate economic activity. We have to take

entrepreneurial kinds of approaches.”

Dr. Chowdary is undeterred, and with the MSc

programme and the addition of the 3D scanner and FDM

machine to the CNC laboratory, manufacturing engineering

has made concrete progress within the university.

Currently he is developing plans to target niche areas for

manufacturing, such as components for the agriculture,

automobile and aerospace industry.

“We are taking small steps, he says, “looking for that

area where we can manufacture a competitive product.

I want to show the strength of this university and this

department, as well as the people of T&T.”

And to truly make it happen, manufacturing

engineering’s number one advocate cannot do it alone. If,

as is often stated, diversification is urgent andmanufacturing

is viable, the Department of MME within the Faculty of

Engineering at UWI St Augustine is developing a powerful

tool for future prosperity. And as any tool it has to be

used.

“This ismy purpose.This ismy aim,” says Dr. Chowdary.

“If the stakeholders are ready I ammore thanwilling to share

my expertise so that we can make it happen.”

TheFDMProcess

FDMtechnology forms

3D objects (specifically rapid prototypes) from

computer generated models. A temperature

controlled head extrudes froma thermoplastic

wire spool that builds an item, 2D layer by 2D

layer, until it forms a complete 3D object.

In general, the manufacturing process can be

broken into five stages.

1.

Create a 3D solid part model through a

computer aided design (CAD) package.

2.

Export the 3D model to the FDM

software in stereo lithography (STL)

format.

3.

Slice the STL model into 2-dimensional

(2D) sections or contours.

4.

The 3D printer (FDM) builds the

prototype using thermoplastic by

applying 2D layer upon layer.

5.

Post-process the prototype by cleaning,

curing and finishing.

Union Matters

On June 24,

we signed the agreement

with WIGUT. A historic good moment

for our Campus as the agreement was

signed within the triennium - without any

disruption to classes, exams etc. WIGUT

understood the state of the economy

and the challenges currently facing The

UWI.

Negot i at ions with the OWTU

for revised terms and conditions of

employment for both the daily rated

and monthly paid workers are ongoing.

We are hopeful that the Office of the

Chief Personnel Officer will give us the

necessary guidelines to conclude these

negotiations shortly.