4

UWI TODAY

– SUNDAY 4 FEBRUARY, 2018

ENTREPRENEURSHIP

“Good chocolate is like a good piece of music,”

says Dr.

Darin Sukha: as you sample it, you’ll experience different

flavour notes which combine to make a memorable

harmony. It’s like an aria of taste, or meditating with your

mouth: a quiet adventure in sensory pleasure.

Fruity or floral, roasted or subtly spicy, the possibilities

of chocolate flavours are endless. Some chocolates may have

hints of jasmine or salty caramel, while others may seep

into your tastebuds like dark velvet rum at midnight. But

it takes skill, knowledge, imagination, and excellent cocoa

beans to achieve true deliciousness.

Flavour, like smell, is deeply linked to our emotions

and memories. In cocoa beans, almost everything helps

shape the flavour, starting from the genetic makeup of

the cocoa plant, to the soil from which the plant draws

nutrients, to the quality of the sunshine and the rainfall,

“terroir” as the French call it. After you collect the beans,

how you choose to ferment, dry, and process them to best

bring out their body and richness is especially important

for developing flavours.

With a passion for cocoa and fine chocolate, Dr. Sukha

leads the Food Technology Team at the Cocoa Research

Centre (CRC) at UWI St. Augustine. He is very excited

about the new chocolate factory in Mt Hope which is soon

to be built. It has been his dream.

At the time of this interview, he was in Brazil, testing

new machinery for the chocolate factory. The factory will

be part of the International Fine Cocoa Innovation Centre

(IFCIC), a project being partly funded by a €2million grant

from the European Union/African, Caribbean and Pacific

Science and Technology Fund.

The IFCIC is the brainchild of plant genetics expert,

Professor Pathmanathan Umaharan, who leads the

Cocoa Research Centre tucked away in a wing of the

Frank Stockdale building at The UWI. The IFCIC aims

to rejuvenate our cocoa sector by helping to develop and

spread better technologies, skills and quality products, as

well as seed a lively, delicious, indigenous cocoa culture.

IFCIC partners include the European Union, the African,

Caribbean and Pacific Group of States, the ACP Science

& Technology Programme, The UWI, and the Caribbean

Fine Cocoa Forum.

The IFCICwill comprise a chocolate factory, a business

incubator facility, a living museum of cocoa plants, a

cocoa tourism centre, a restaurant, kitchen and labs, and a

Chocolate Academy for courses in chocolate making. The

chocolate factory will produce cocoa nibs, cocoa liquor (the

unsweetened liquid base for chocolate), and couverture

or finished chocolate (both dark and milk). The idea is

to have a total bean-to-bar model to stimulate the sector

and enable applied research to have real community and

industry impact.

Dr Sukha sits on a panel of judges for the International

Cocoa Awards, of the Cocoa of Excellence Programme,

a global competition celebrating the diversity of cocoa

flavours, held every two years since 2009. There he gets to

taste some of the world’s best-flavoured cocoa. The 2017

competition received 166 samples of fermented and dried

cocoa beans from 40 countries: “Some of the flavours will

blow your mind!” he said.

Dr Sukha wants to help T&T cocoa producers develop

their own equally wonderful flavours. Trinidad is uniquely

positioned for this, because we grow Trinitario cocoa, one

of the world’s finest.

“While bulk cocoa beans, which are 95%of the market,

might sell for about US $2,000/ton, fine flavour beans (5%

of the cocoa market) sell for US$5,000-US$10,000/ton,”

says a senior CRC staffer.

There’s much money to be made from cocoa’s most

popular product, chocolate. Chocolate is one of the

best-loved foods on the planet, with global retail sales of

US$101 billion in 2015. But so far, the lion’s share of cocoa

profits is being made by a few big multinational chocolate

manufacturers and retailers in the global north, such as

Mars Inc (USA), Mondelez International (USA), Nestle

SA (Switzerland), and Ferrero Group (Luxembourg/Italy).

As T&T cannot compete with big bulk chocolate firms,

it makes sense to focus on high-end, high-quality niche

cocoa products. The IFCIC chocolate factory is one step

towards this. It aims to boost local expertise in making

excellent, unique home-made chocolate and other cocoa

products.

To accomplish this requires several things, including

access to good and plentiful local cocoa stocks, training

in manufacturing processes, access to a factory, and

developing the craft and taste sensibility to discern, enjoy

andmake good chocolate flavours. Genetic research into the

cocoa plant itself can help develop better tasting, resilient

varieties.

The Cocoa Research Centre has had a head start on

such genetic research. It is home to the International Cocoa

Genebank, the largest collection of cocoa varieties in the

world, with 2,200 varieties. The CRC also has more than

80 years of research under its belt through its previous

incarnations as the Cocoa Research Unit, and the Cocoa

Research Scheme (formed in 1930 under the Imperial

College of Tropical Agriculture).

In addition to its scientific research, the CRC also

provides certification, post-harvest support, chocolate-

making support, DNAfingerprinting, breeding support and

disease screening, paid services for clients throughout Latin

America and the Caribbean, earning some useful foreign

exchange. And it has been running its own tiny in-house

chocolate factory in UWI since 2012, making a 70% dark

chocolate bar from local cocoa.

Prof Umaharan has long had a vision for the huge

potential development of not only the T&T cocoa industry,

but also the local anthurium and hot pepper sectors. But

visions remain dreams until they are funded. So Prof

Umaharan, six years ago, on behalf of the CRC, applied to

the UWI’s RDI Fund to do a special project on the genetic

control and identifying markers for some specific cocoa

traits. The project, approved in 2012, looked at cocoa

yield, pod characteristics, disease resistance, cadmium

bioaccumulation, rooting characteristics and flavour.

The project has since become a rising star among

UWI’s RDI-funded projects because its findings attracted

significant additional external funding to support more

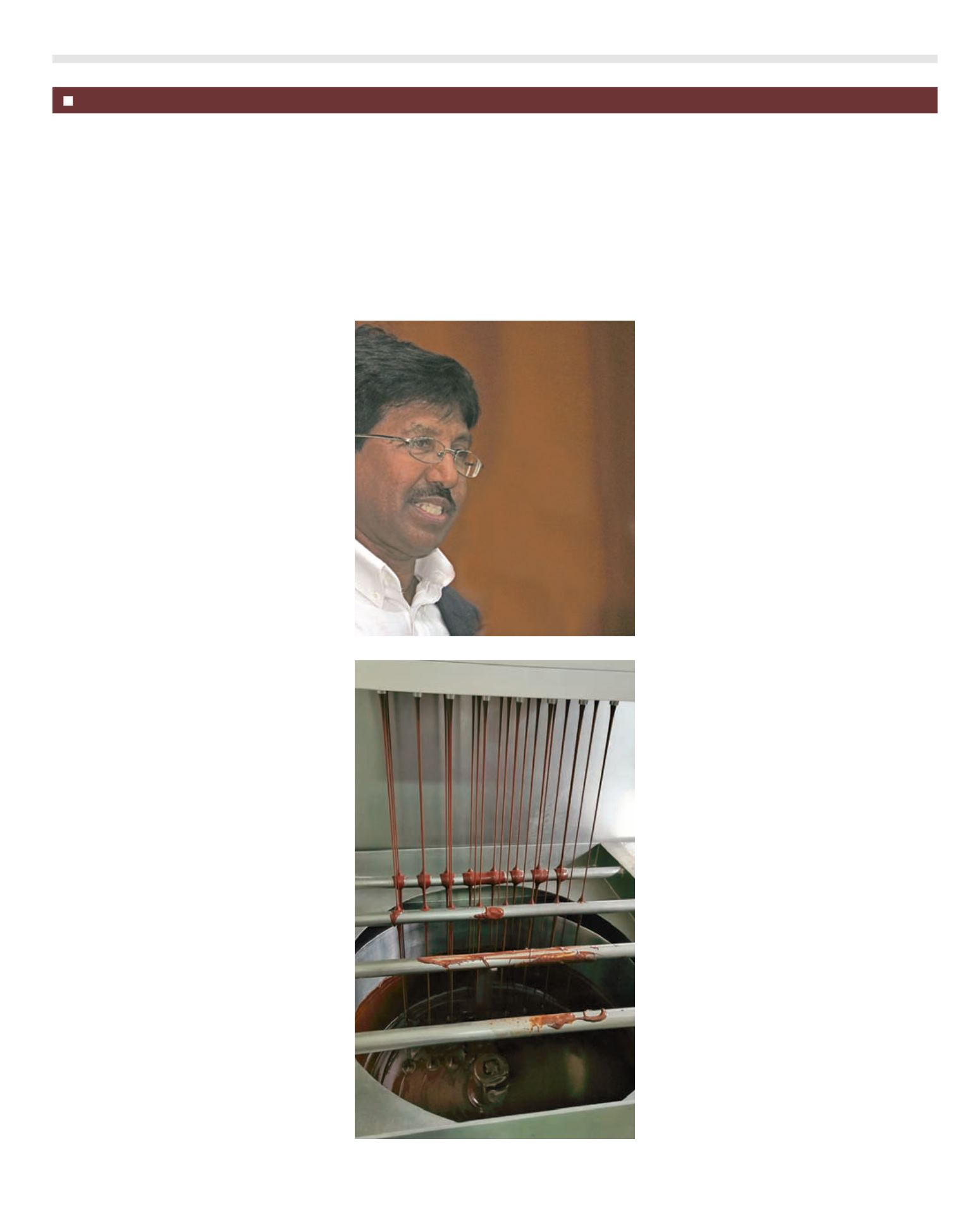

In Brazil, chocolate tempering for moulding: The chocolate factory

will produce cocoa nibs, cocoa liquor (the unsweetened liquid base for

chocolate), and couverture or finished chocolate (both dark and milk).

Building the

COCOA DREAM

Blocks of Chocolate

B Y S H E R E E N A L I

Professor Pathmanathan

Umaharan at World

Chocolate Day event

in 2017. The chocolate

factory will be part

of the International

Fine Cocoa Innovation

Centre (IFCIC). The

Centre will comprise

a chocolate factory,

a business incubator

facility, a living museum

of cocoa plants, a

cocoa tourism centre, a

restaurant, kitchen and

labs, and a Chocolate

Academy for courses in

chocolate making.