UWI offers lubrication expertise

The UWI St. Augustine Campus has developed considerable expertise in the field of tribology—the science and technology of controlling friction, lubrication and wear—and can now offer its expertise in lubrication problems to local companies wishing to review their current processes. As the properties of lubricants are enhanced, one major advantage for the consumer is that the amount of “downtime” for equipment will be reduced. The Faculty of Science and Agriculture can assist companies seeking an understanding of which lubricants work best in their machinery through customized assessment and consultation. The UWI St. Augustine Campus has developed considerable expertise in the field of tribology—the science and technology of controlling friction, lubrication and wear—and can now offer its expertise in lubrication problems to local companies wishing to review their current processes. As the properties of lubricants are enhanced, one major advantage for the consumer is that the amount of “downtime” for equipment will be reduced. The Faculty of Science and Agriculture can assist companies seeking an understanding of which lubricants work best in their machinery through customized assessment and consultation.

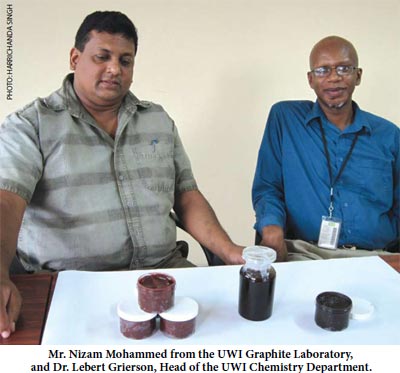

Dr. Lebert Grierson, Head of the UWI Chemistry Department, said that UWI researchers continue to develop indigenous expertise and seek solutions that meet local demand. The team is prepared to provide clients with expertise and training that takes into account the peculiar circumstances in which they operate as well as their specific requirements. Dr. Grierson explained that the consultancy services also cover design issues that must be addressed if companies are to improve their overall performance and reduce costs.

The UWI Graphite Laboratory has already developed products that have been tested locally and found to be superior to those currently on the market. One such product is a heavy-duty grease designed for use with heavy equipment and bearings. The same grease is also suitable for marine applications. Unlike competitors’ products, the grease has been formulated to work as a multi-purpose product for various pieces of equipment, saving money and reducing maintenance time.

The Laboratory has also developed several asphalt-based products, including a multi-purpose plastic cement which can be used to seal cracks in concrete and metal, including walls and roofs. The Laboratory has developed a lubricant that can be used in open gears and wheels and can also be used as a catalyst for thickening other oils.

Mr. Nizam Mohammed, the Laboratory’s main product developer, has been conducting lubricant and asphalt research and testing for several years and can develop specialized lubricants to meet a myriad of lubrication problems experienced in cement manufacturing, quarrying, and light and heavy industries. Due to its flexible nature, the Laboratory has the ability to customize products to meet specific customer requirements.

Funds generated from the services provided by the research team are channeled back into the University’s research and innovation efforts. Dr. Grierson states that such funds may be used to acquire state-of-the-art laboratory equipment such as four-ball testing and friction equipment and a dynamic shearing rheometer.

Companies interested in accessing the University’s tribology services in lubrication or in collaborating with the University to further develop or market its graphite- and asphalt-based products locally or in the wider Caribbean are invited to contact the UWI Business Development Office by email to development@sta.uwi.edu.

|