14

UWI TODAY – SUNDAY 16 DECEMBER, 2018

70

th

ANNIVERSARY COMMEMORATIVE ISSUE

RESEARCH

– ISSUE ARCHIVE JUNE 2011

The Chataigne

f r u i t

i s w e l l

known in parts

of the Caribbean,

notably Trinidad

and Guyana, as

a delicacy served

in a coconut curry

sauce at special

occasions, such

as weddings and

at Divali.

A close relative of the breadfruit (Artocarpus

altilis), the chataigne (Artocarpus camansi) contains

twice the protein, and its seeds are low in fat compared

with nuts such as the almond, brazil, and macadamia.

Known in the region as the bread nut or katahar

(Guyana) it is prized when ripened for the seeds, and

when mature, but not ripe, it is prepared in delicately

flavoured curries.

To do this, the thick, spiky skin must be removed,

and the flesh shredded apart by hand after the seeds

are painstakingly removed. Served with roti (paratha)

along with other vegetables, it is a popular dish at

weddings and other functions.

While the demand for curried chataigne has been

growing, the task of peeling and preparing the fruit is

so labour intensive that it makes it almost prohibitive.

A typical wedding might require 300 chataigne

fruits for a side dish, and this would take about 12

man-days for preparation, i.e. peeling, shredding and

then preparing the seeds before cooking. No wonder

it has remained such an occasional delicacy!

That might soon be a thing of the past.

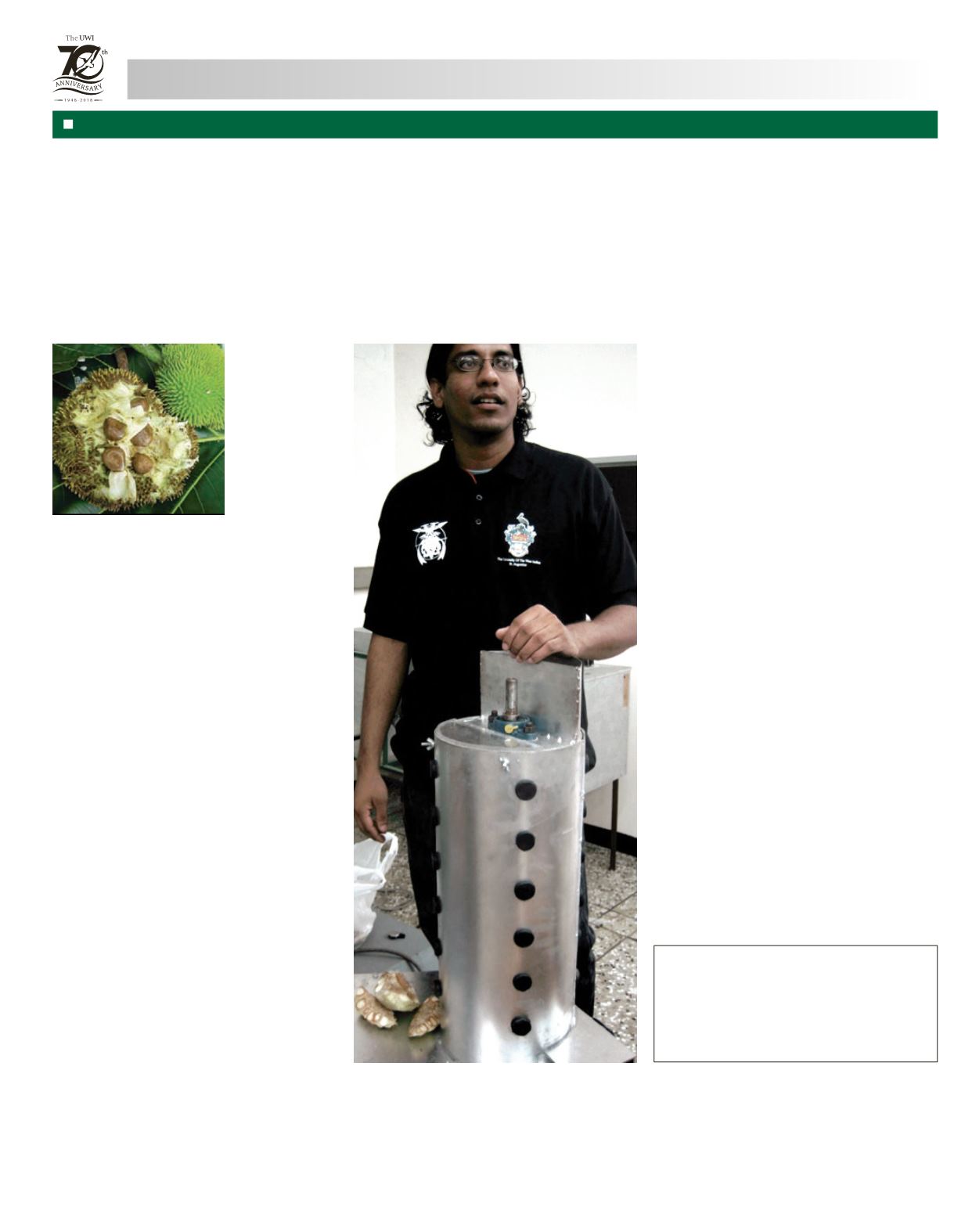

Nishad Gopaulchan, a final year Mechanical

Engineering student at The UWI, has designed and

built a simple machine that can prepare 100 chataigne

fruits in an hour.

DEVELOPING THE MACHINE

Various methods for separating the seeds from

the fibrous inner core of the fruit were considered and

these included friction, brushing and impact, however

the one that showed the best potential was impact.

Initial trials with steel rods impacting on the inner

core of the fruit, left bruises or marks of injury on the

final product. Although this could be minimized and

managed, it showed up as brown to blackmarks on the

product when kept refrigerated for awhile.

TheChataigne Peeler

Student’s machine could put this delicacy on your table every week

B Y R O D N E Y H A R N A R I N E

Replacing the steel rod beaters with a steady

rubber one, minimized, if not eliminated, the problem

of impact injury on the finished product.

Placing the rotating and stationary rubber fingers

was a critical factor in the design, as the spacing must

be appropriate to allow the flow of the separated fiber

and seeds through the machine without clogging and

“sticking” the machine.

The machine is powered by a single phase 110

Volt motor; hence it can be plugged into any domestic

household electric supply.

The machine is ergonomically designed; the

hopper is at the top and can be easily reached by the

average adult while the lower chute allows enough

height to place a receptacle to collect the finished

product. There are no sharp edges or projecting

bolts that could create risks for injury to users of the

machine.

COMMERCIAL POTENTIAL

FOR THE MACHINE

The machine was on display at both the recently

concluded Sci-technofest, run by NIHERST and the

Open Day at the Faculty of Engineering; without

quoting a price for the machine, more than 100

persons have indicated an interest in having one of

these machines.

Among those who have expressed interest, caterers

were the largest group. At the Faculty of Engineering

at UWI, we see this as a wonderful opportunity

to expand the consumption of local cuisine, with

its attendant backward linkage with agriculture,

while simultaneously creating the opportunity to

commercialize our homegrownmechanical, machine-

building skills.

The project has a high potential for success both

locally and internationally.

Rodney Harnarine is a development engineer

at the Department of Mechanical and

Manufacturing Engineering, at The UWI, St.

Augustine. He supervised the construction of

Nishad Gopaulchan’s Chataigne Peeler.

“A typical wedding might require 300 chataigne fruits for a side dish, and this would take

about 12 man-days for preparation ...that might soon be a thing of the past.”

Nishad Gopaulchan

with the chataigne

peeler machine.